I have used over 3Kg of ABS without a single successful complete print. The problem was that at some point during the print the extruder controller would shut off the extruder heater for no apparent reason. Obviously this stopped molten ABS from flowing out of the extruder and I had to abort the print.

I tried all sorts of settings when generating the GCode cos folks on the RepRap forums indicated that the problem might be with the code, but had no luck there. I was quite sure that the problem lied within the hardware and when I exhausted all my other options I fired out an e-mail to Kimberley of Techzone asking for help in solving this issue. She did promptly come back to me as usual, but the answer was that I need to wait till Tuesday when the guy that can help me returns from an exhibition they are attending.

As they say, necessity is the mother of invention. I thought to myself that building an independent heater controller shouldn't be rocket science (even if it was I was determined to succeed). A quick scavenge through my pile of junk and the neatly packed stuff that my girlfriend owes (she is also an electrical engineer) resulted in an interesting find. A couple of TIP3055 (Data-sheets http://www.bourns.com/pdfs/tip3055.pdf) capable of handling 10 Amps. True, this transistor is an overkill but there again, I'm eager to get a complete print.

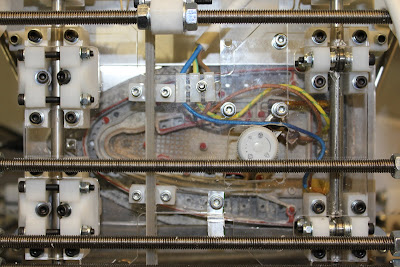

A couple of quick calculations led to the following circuit diagram which I built on a "breadboard" (technical term for prototyping board), connected to the extruder heater and fired it up..... Fantastic!! Seems to work!

The components in blue are off-board and I inserted scavenged connectors on the strip board I set out to build. Below are images of both the front and rear of the board for anyone that wishes to build one. The idea behind this circuit is that when the Thermistor (which is an NTC - Negative Temperature Coefficient - which means that with rising temperature the resistance decreases) is heated up, and its resistance decreases, the voltage across the resistor decreases until it switches off the transistor. With the transistor off, the extruder heater is also off so it begins to cool. This results in the thermistor increasing its resistance and hence voltage drop which triggers the transistor again. The result is that the transistor/thermistor combination find a happy medium and settle at an ideal state where the temperature is roughly constant. This is also known as a Proportional Controller. The LED is a simple indicator of when the temperature is at its pre-set state since when the transistor switches off, the current flows through the LED turning it on. The LED is dimmer than usual when the transistor/thermistor are in equilibrium. If the LED is brightly on, then the temperature is too high and the transistor (and hence the heater) would be turned off at that time.

|

| Component Side |

|

| Solder side |

Loaded the GCode and hit print..... All was well up to layer 23 when the extruder motor stopped working, but at the next layer it started again so no great loss there. At layer 48 it did it again, but this time it didn't restart at the next layer and neither the following (see gap in finished product) I waited until the printer went to its zero position between layers and hit the Reset button on the extruder controller. Luckily it started extruding again.

At layer 97 it did it again, but this time I hit the reset button immediately as it went to the zero position. It worked and the printer continued to finish the product....

Finally an entire print, although I had messed up the settings so much that it will be binned anyway. Hopefully by tomorrow I'll have a decent print to post as this is no looker.

|

| A somewhat finished product |