The idea was to stick the iron to a lower bed that heats up and distributes heat as evenly as possible to avoid hot-spots while transferring that heat to a flat, removable print bed held on by binder clips as per Adrian Bowyer’s reprap printing video.

This was no budget purchase... the sheets would cost nearly £60 but I needed a quick and decent solution as this build has now taken over 100 hours and I’m running out of time as Uni starts soon (and very looking forward to it!)

On my way to the checkout counter I spotted something interesting.... An aluminium shelf, probably for fitting in a bathroom. I measured it up and the width was just 2mm short of what I needed.... perfect!. The cost was just £14 something. The only downside was that the edges were turned to 90 degrees on one side and two 90 degree turns on the other forming a ‘C’... nothing that a hacksaw and a file can’t solve, so I ditched the steel sheets and headed for the checkout counters knowing that I made a bargain.

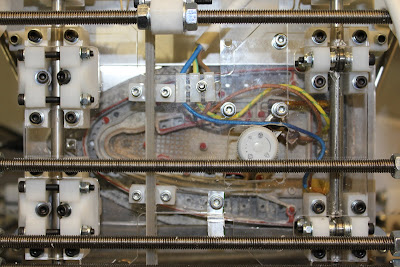

Once home, I hacked through the aluminium shelf to produce 2 identical reprap size beds. On one I bolted on the iron with the same method I used before (i.e. two strips of aluminium pressing down the iron by the mounting bolts of the bed), on the other I drilled 10mm holes in place where the mounting bolts go so that the bolt head and the washer won’t create a gap in between the two sheets of aluminium.

It took me all day to finalise these (and not without its mishaps). When everything was assembled I powered on the reprap and started per-heating the extruder. I wanted to test on a cold bed first to make sure everything was aligned and working. While having a cuppa, I noticed that the temperature of the extruder wasn’t increasing. I reset everything and tried again, but it’s still a no go, even after a number of retries. I touched the components on the extruder board to see if any of them were heating up and to my amazement the nozzle heater started working as soon as I touched the Atmel processor.

This only lasted a short while. After close inspection I realised that the processor had such bad soldering that my neighbour’s cat could have done a better job. Techzone seem to have very poor QC. Luckily their customer service compensates for this. I had already reported issues with my extruder board last week and they agreed to send me a new one free of charge and should arrive early this week.

Third attempt to be continued...

This comment has been removed by a blog administrator.

ReplyDelete